Our company’s 1000 concrete mixer has the advantages of long service life of the liner and blades, convenient maintenance and so on. It is suitable for mixing plastic, dry hard, lightweight aggregate concrete and various mortars and mortars.

InquiryJS1000 forced concrete mixer is the advanced ideal construction equipment model in domestic and abroad.The liners & blades have the advantages of long service life, easily maintenance.Suitable for mixing plastic, dry hard, light aggregate concrete and various mortars and mortars.

This mixer adopts motorized discharge method, can use together with tipper car,dumper truck or mixer truck.

Applicable to all kinds of large, medium, small precast components factories as well as industrial and civil construction projects such as roads, bridges, water conservancy, and docks.

This mixer is possible to mix dry hard concrete, plastic concrete, fluid concrete,Lightweight aggregate concrete and variouos types mortar.

The concrete mixer produced by Jianxin is connected to the transmission mechanism via a shaft: the gear meshes with the gear ring installed on the cylinder body.

The utility model has a simple and reasonable structure. The use of gears and ring gears can effectively overcome the slippage between the roller and the mixer drum during rain and fog.

The transmission mechanism used can further ensure that the skidding between the roller and the mixer drum is eliminated.

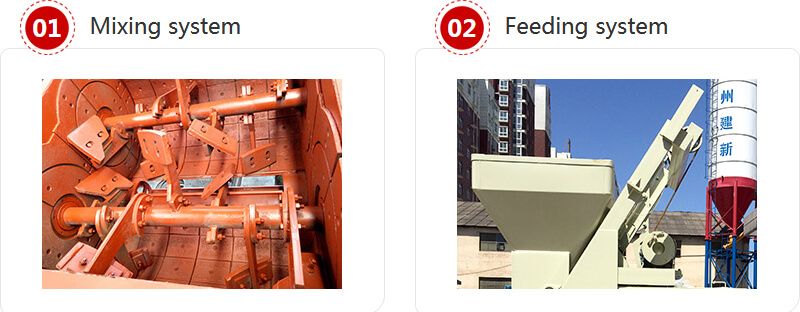

JS1000 concrete mixer Mixing system

The mixing system consists of pulleys, reducers, open gears, motors, mixer drums oil supply units and other mechanisms. A special sealing device is provided at the junction of the stirring shaft and the two ends of the mixing drum. In order to ensure the quality of the seal, a special oil supply is provided on the end face of the mixer drum.

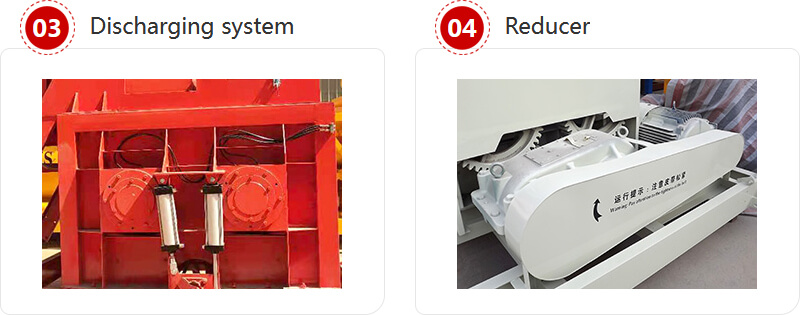

JS1000 concrete mixer Feeding system

The brake motor drives the reel to rotate through the reducer, and the wire rope climbs up along the loading rack rail through the pulley pulling hopper. When it rises to a certain height, a pair of rollers above the bucket door at the bottom of the hopper enters the water rail of the loading rack, and the bucket door automatically opens. The material enters the mixing drum through the feed nozzle.

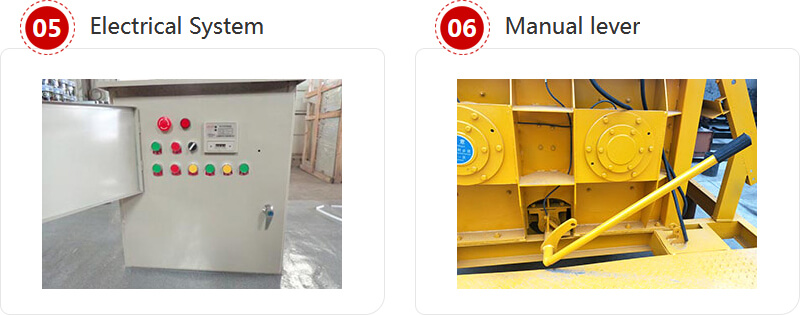

JS1000 concrete mixer Discharging system

The discharging system consists of a discharge door, a gas pump, a reversing valve, a gas distribution valve, a cylinder, an electric and other mechanisms. The discharge door is installed at the bottom of the mixer and is pneumatically discharged through the cylinder. The discharge gate seal can be ensured by adjusting the position of the seal.

JS1000 concrete mixer Electrical System

The electric control circuit is equipped with an air switch, a fuse, and a thermal relay, and has the functions of short circuit protection and overload protection. All control buttons and air switch handles and indicators are placed on the distribution box door with a door lock. A protective cover is placed outside the button. The electrical control power supply is a 380V three-phase four-wire power supply with a voltage tolerance of ±10%, otherwise it is forbidden to use. If the user has their own power generation, the capacity shall be ≧100KVa. The surface temperature rise of the motor ≧ 60 ℃, the live part ≧0.5MΩ to the shell edge.