The YHZS75 mobile concrete mixing plant has a compact structure. The loading, weighing, mixing and other processes of concrete production are concentrated on a trailer unit; the man-machine interface is simple and clear, the work is stable and reliable, and it is suitable for various harsh environments.

InquiryYHZS75 mobile concrete mixing station is mainly used for mixing and building high-grade highways, urban roads, airport runways and other paving concrete, roadbed concrete, roller compacted concrete, precast concrete, and commercial concrete for mixing construction. The whole set of equipment is compact, and the process of feeding, weighing, stirring and other processes of concrete production is centralized on a trailer unit; the man-machine interface is simple and clear, the work is stable and reliable, and it is applicable to various harsh environments; the whole machine design meets the environmental protection requirements , excellent mobile performance; the use of double-shaft forced mixer, continuous work ability, stirring evenly and quickly, suitable for multi-line long-term concrete construction requirements.

1、Mixer system

The 1500 concrete mixer is mainly divided into gate valve concrete pump and S valve concrete pump, but according to the structure, it can be divided into piston type, squeeze type, and hydraulic diaphragm type. The pump body is installed on the chassis of the car. The telescopic or inflexible placing boom forms a pump truck, which is mainly used in housing construction, bridge and tunnel construction.

2、Mixer system

MPC1500 vertical shaft planetary mixer is also called 1.5 square planetary concrete mixer. Jianxin Machinery’s vertical shaft planetary mixer adopts advanced technology. The whole machine has stable transmission, high mixing efficiency, high mixing homogeneity, and unique sealing device without slurry leakage. , Strong durability, easy to clean the interior, and large space for maintenance

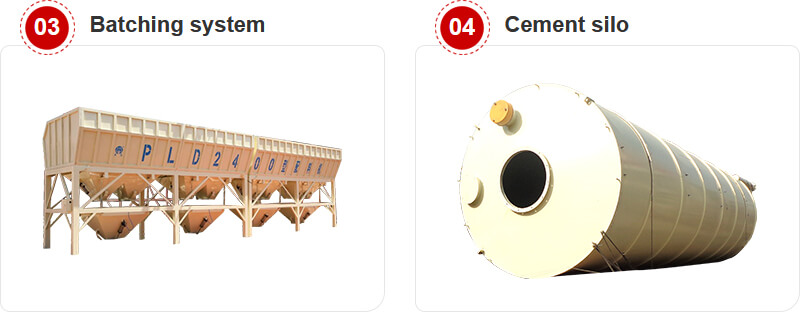

3、Batching system

The PLD2400 concrete batching machine can effectively ensure the accuracy of the mixing ratio of cement, sand, stone, etc., and the use of an electronic weighing system further improves the accuracy of weighing. The top panel of the batching machine can be lowered or removed as required, which can greatly reduce the labor intensity of the feeding part and increase the convenience of construction.

4、Cement silo

The cement silo is divided into three types: bolted cement silo, integral cement silo, and horizontal cement silo. The upper and lower parts of the cement silo are equipped with level gauges and dust removal systems; in order to prevent the powder from arching, a blower is installed at the cone of the silo Arch breaking device; it can be designed as a sheet cement warehouse, which is convenient to transport and easy to use.

5、Conveying system

The aggregate conveying system adopts the lifting bucket feeding method, which has the advantage of occupying a small space and saving land resources. Belt conveyor is an ideal high-efficiency continuous transportation equipment. It has the advantages of long transportation distance, large transportation volume, continuous transportation, etc. It is easy to realize automation and centralized control.

6、Control System

The control room is at the bottom of the main chassis, and the mixing plant fully automatic control system is installed inside. The control system is the same as the fixed mixing plant. The control room is used as the front support point of the whole station when it is working. The control room is stowed and stored in the bracket during transfer. Inside; all its control circuits do not need to be disassembled.